| Request more

This e-mail address is being protected from spam bots, you need JavaScript enabled to view it

|  - central units in rotary special-purpose machines for transporting workpieces and positioning them accurately in each machining station

- workholders in standard and special-purpose machine tools for efficient, ultra-precise workpiece machining

- controllable and highly versatile positioning devices for machining workpieces from different angles

- toolholders for high-speed tool changes on a wide variety of machine tools

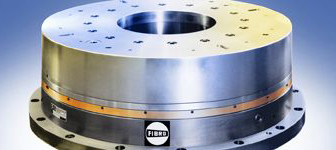

FIBRO’s comprehensive range of rotary indexing tables offers users any number of options for rationalizing and automating production processes, and of course for enhancing production quality.

Rotary indexing tables are available in any format or size from 6" to 63" in diameter. |

|

Rotary Tables for Machine Tools

FIBROTAKT® indexing tables have been designed for precision divisions and high working loads. Interlocking in the FIBRO face gear ensures maximum precision and rigidity long term. There are different versions and drive types to suit very application. Whatever the assembly weight, the built-in FIBROTAKT® indexing table for phased indexing machines combines minimum switching times with maximum precision and rigidity. It features a non-lifting indexing table, gear drive and easy access from below.

|

|  FIBROTAKT® Flush-Mount Tables were developed for use on rotary transfer machines. The concept derives from the well-tried FIBROTAKT®-series and is based on the principle of combining indexing and locking in a non-lifting system of face gear rings. FIBROTAKT® Flush-Mount Tables were developed for use on rotary transfer machines. The concept derives from the well-tried FIBROTAKT®-series and is based on the principle of combining indexing and locking in a non-lifting system of face gear rings.

|

|

The FIBROMOD rotary table series has a modular structure and covers all machine tool requirements within one system. In addition to the use of standardized construction principles, the basis for this is in particular the carefully considered use of clever interfaces. FIBROMOD series allows an easy accessibility and individual adjustments even after many years of industrial production. The FIBROMOD rotary table series has a modular structure and covers all machine tool requirements within one system. In addition to the use of standardized construction principles, the basis for this is in particular the carefully considered use of clever interfaces. FIBROMOD series allows an easy accessibility and individual adjustments even after many years of industrial production.

|

|

FIBROPLAN rotary tables are equipped with a backlash-adjustable worm drive for machine tools for universal positioning. Rotary and multiple-axis machining (simultaneous operation) is possible. FIBROPLAN rotary tables are equipped with a backlash-adjustable worm drive for machine tools for universal positioning. Rotary and multiple-axis machining (simultaneous operation) is possible.

The application of high-resolution measuring systems and the special design features with high-precision, rigid bearing results in high positioning accuracy.

|

|

|

FIBROMAX 2.0 second-generation heavy-duty positioning table convinces with high rigidity and energy efficiency. With the FIBROMAX 2.0 series, FIBRO presents a completely reworked series of its high-performance XXL rotary shift tables. FIBROMAX 2.0 second-generation heavy-duty positioning table convinces with high rigidity and energy efficiency. With the FIBROMAX 2.0 series, FIBRO presents a completely reworked series of its high-performance XXL rotary shift tables.

Compared to the first generation, the bearing diameter and thus the rigidity of the heavy-duty positioners have grown significantly.

|

|

|

A turbo among rotary tables – the new FIBRODYN DA direct driven rotary tables with torque motor are optimally suited for all handling and assembly applications that require the shortest indexing times and flexible positioning. Thanks to its measuring system directly in the rotary table axis, any position can be moved to with the highest precision. The slim design with its very space-saving, compact construction and its fitted boreholes makes it very easy to integrate the rotary tale into your system. A turbo among rotary tables – the new FIBRODYN DA direct driven rotary tables with torque motor are optimally suited for all handling and assembly applications that require the shortest indexing times and flexible positioning. Thanks to its measuring system directly in the rotary table axis, any position can be moved to with the highest precision. The slim design with its very space-saving, compact construction and its fitted boreholes makes it very easy to integrate the rotary tale into your system.

|

|

Rotary tables for automation systems

Rotary Indexing Tables with planetary units are the "Specialists" when it comes to multi-face machining on Rotary Transfer Machines. Their arrangement details are as varied as are the workpieces and the machining requirements. FIBRO, with their immense experience inFibro Planetary Indexing Systems the entire field of rotary indexing, have the specialists, the equipment, and a vast range of batch-manufactured indexing elements to meet the most exacting demands.

FIBROTOR® indexing tables are designed with a worm roller drive for optimised rapid switching operations. They are used in welding and assembly operations, as a magazine table and for handling and feeding applications in automated processes. FIBROTOR® NC indexing tables have a worm roller drive of constant pitch. Any size of divisions are possible when used in conjunction with NC control. FIBROTOR® indexing tables are designed with a worm roller drive for optimised rapid switching operations. They are used in welding and assembly operations, as a magazine table and for handling and feeding applications in automated processes. FIBROTOR® NC indexing tables have a worm roller drive of constant pitch. Any size of divisions are possible when used in conjunction with NC control.

Models:

|

|  A powerhouse with an extremely large center hole and very flat design at an optimum price — the FIBROMAT heavy-load positioning tables from FIBRO. A powerhouse with an extremely large center hole and very flat design at an optimum price — the FIBROMAT heavy-load positioning tables from FIBRO.

When large and heavy fixtures have to be positioned dynamically and precisely, the FIBROMAT modular heavy-load positioning table is the optimum solution. It fits perfectly into automobile body in white, as the heart of work piece storages or in honing centers, for example. The maintenance-free rotary table with lifetime lubrication is driven by reliable spur gear drive. |

|